There are basically two different methods of whisky distillation. The first is distillation in pot stills and the second is production in column stills. This is a column distillation process. The whisky is usually distilled two or three times. The low wines with an alcohol content of approx. 20% are produced in the first distillation and the high wines with an alcohol content of 60 to 70% are produced in subsequent distillations.

Pot stills

- Scotch whisky, double or triple distillation

- Irish whiskey, double or triple distillation

- Japanese whisky, double distillation

- Other whiskies such as German and European

The principle of distillation

The principle of distillation was already known to the Egyptians. Substances can be separated from each other by heating them to different vaporisation temperatures. The substances that evaporate first at low temperatures can be collected and thus separated from the rest. However, the Egyptians only knew distillation for perfume production. It was not until the Middle Ages that Celtic monks discovered the production of whisky, the water of life!

Due to alcoholic fermentation, the wash (beer) contains around 8 to 10% alcohol (ethanol = ethyl alcohol). The alcohol content depends on the yeast used and the duration of fermentation.

If the wash is heated, the substances that boil earlier than water evaporate from the beer as the temperature rises. The mixture of water and alcohol results in a new boiling temperature. An alcohol-water mixture with an alcohol content of 8-10% results in a boiling temperature of around 93°C. Further heating above this temperature causes the mixture to boil. During boiling, the alcohol content of the mixture decreases as the alcohol evaporates faster than the water. The alcohol content in the vapour is higher and the alcohol content in the remainder of the bubble is lower.

Pot still distillation

This article deals with the operation of the stills. Of course, there are differences between the stills of different distilleries. Some heat quickly and then distil slowly, others heat quickly and also distil quickly. It is not only the geometric shape of the still that determines the taste of the raw whisky, it is above all the distillation process that significantly influences the taste and the flavours present in the raw whisky.

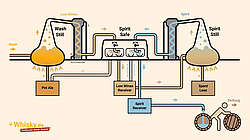

The following diagram shows the basic structure of a Scotch malt whisky distillery with two stills and the distillation process. Distilleries with triple distillation and three stills are extended by one stage. Many larger distilleries have four, six or even more stills, which are not operated in sequence but in parallel pairs.

The interconnection of the stills can be even more complex if, for example, the first distillate from several wash stills or several production runs of a single wash still is channelled to a single spirit still. A 3:2 or 4:3 ratio of wash to spirit stills is also common. It is also possible to triple distil on two stills by returning the end product of the second distillation in the spirit still as a whole to the empty spirit still.

The Wash Still

The task of the wash still is quickly described. It is used for the first distillation of the mash, also known colloquially as beer. The capacities of the still and the fermentation tank (wash back) are usually matched to each other. 15,000 to 30,000 litres are the norm.

The wash is heated by introducing hot steam into the heating cylinders of the wash still. The heat movement (convection) within the still circulates the wash. It rises at the hot points of the heating cylinders and sinks again at the cooler points.

After about half an hour, the time has come. The liquid begins to boil above the heating cylinders and light substances (especially flavour-bearing esters) rise into the air space above the liquid level.

The constant supply of gaseous substances creates a slight overpressure in the still and the gases rise into the neck of the still. But they don't get very far. The wall of the still is still too cold and the vaporised substances settle in small droplets on the wall of the neck. Over time, more and more droplets collect on the wall and combine to form larger droplets, which flow back into the wash still's boiler in accordance with gravity.

As more energy is added, the entire wash begins to boil at a temperature of around 78 degrees. The entire still heats up and the surface of the liquid becomes turbulent. The high heat supply causes large bubbles to form and the liquid foams up and splashes into the upper neck of the wash still.

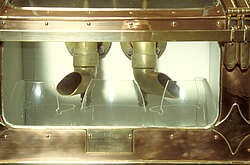

Only the wash stills therefore have glass windows in the neck, behind which the bubbling wash can be observed. If the wash is boiled too high, liquid can enter the condenser via the Lyne arm. This wouldn't be so bad if the wash didn't still contain solid parts of the barley grains, which clog the fine tubes of the condenser.

Great attention is therefore required from the stillman. In distilleries that do not want to take the time for this boiling control, soap is therefore added to the wash, which dissolves the surface tension of the feed and effectively prevents boiling over. As soap becomes liquid at 50 - 60 degrees and only boils at well over 100 degrees, there is no risk of soap molecules passing into the distillate.

The first distillation in the wash still usually takes around 4 to 7 hours. The temperature of the wash still is around 78 degrees. This is the temperature at which ethanol vaporises. The entire heat supply to the pot still via superheated steam is used to vaporise the alcohol.

Low Wines

At the end of the distillation process, all of the alcohol has evaporated down to around 1% by volume and is collected in the low wines receiver.

The low wines receiver contains more than just the pure alcohol. It contains all substances that boil at a lower temperature than alcohol. Substances with a slightly higher boiling point have also been torn out of the molecular bond by the highly effervescent liquid and drawn into the low wines with the light alcohol molecules. These molecules also contain a lot of water, which forms an azeotrope with the alcohol. After the first distillation, the low wines have a typical alcohol content of 20 to 25 % vol.

Pot ale

At the end of the distillation process, the pot ale - also known as spent wash - remains in the wash still with a residual alcohol content of around 1 % vol. However, it is not only alcohol that remains in the liquid. Valuable proteins and minerals from the grain are also found in the pot ale. This is why the pot ale is thickened after draining and sold as high-quality animal feed.

Only a few distilleries have such evaporation plants, as they are associated with high investments. The town of Rothes in Speyside operates such a plant jointly for all distilleries in the area. In order not to lose the residual heat energy of the pot ale, which is still around 70 degrees, during transport in tankers, the pot ale is usually emptied via a heat exchanger, which feeds the heat energy back into a subsequent distillation process.

The large stills have walls that are only a few millimetres thick. They are therefore very sensitive to overpressure and underpressure. The biggest accident a still is likely to suffer is collapse due to negative pressure. When distillation stops, the pot ale is drained and the still cools down, a vacuum is created inside. If this negative pressure becomes too strong, the still collapses with a loud bang. As this has happened more than once in the past, an automatic overpressure and underpressure safety valve is now fitted to every still to equalise the pressure with the environment. For filling and emptying the stills, there is a further ventilation valve, which nowadays is usually operated automatically with the pumps.

Distillation balance 1

The distillation balance of wash still distillation is summarised in the following table.

| Wash | Low Wines | Spent Wash | |

|---|---|---|---|

| Total in litres | 30.000 | 11.252 | 18.748 |

| Alcohol content in % vol | 10% | 25% | 1% |

| Alcohol in litres | 3.000 | 2.813 | 187 |

The figures in the distillation balance show that the reduction in the amount of water from the wash to the low wines - the second distillation quantity for the spirit still - is significantly reduced.

To summarise, it can be said that the first distillation serves exclusively to reduce the amount of liquid to 1/3 and to retain the solid components of the grains that were still in the wash.

As a rule, this first distillation only takes four hours. The influence on the flavour of the finished whisky is therefore minimal. Due to the extreme heating of the wash and the strong boiling of the liquid, in addition to the alcohol and a large amount of water, many heavy fusel oils also pass into the low wines.

The Spirit Still

The second distillation in the smaller spirit stills takes place much more carefully and slowly. Typically, the second distillation takes around 8 hours. As this is twice as long as the first distillation, the result of two wash distillations is often collected together in the low wines receiver and fed into the spirit still as a whole. The spirit still has the greater influence on the flavour of the raw whisky. In order to better separate the alcohol and flavourings from the water, the second distillation is much gentler. For this reason, the stills do not need windows to observe the boiling low wine.

The distillation process as such takes place in exactly the same way as with the wash still. The feed is heated and before the evaporation temperature of the ethanol (78 degrees) is reached, the volatile foreshots that evaporate earlier rise to the surface. These foreshots are mainly light compounds such as ethyl acetate and volatile esters, which have a pungent flavour.

The Spirit Safe

In the Spirit Safe, the whisky is divided into three parts:

Foreshot - Middle Cut - Faints

or also

Head - Heart - Tail

Only the heart is used!

The aggressive foreshots are undesirable in raw whisky and are therefore not channelled into the collection container by switching the distillation flow in the Spirit Safe.

The spirit safe has a long history and a special task. With distillation, the British customs authorities require all stills and pipework to be sealed. The stillman therefore has no opportunity to sample the raw whisky. So how does he know when the foreshots have run through and the good-tasting centrepiece of the distillation has begun?

Alcohol measurement

Experience teaches the stillman as a first clue the time of heating up to the appearance of the middle cut (centrepiece). Firstly, there is a long period of heating until the first distillate is visible in the spirit safe. After all, thousands of litres have to be heated to over 70 degrees. The foreshots then run for around 20 minutes. In order to accurately determine the switchover time for collecting the centrepiece, the Spirit Safe contains several glass containers in which the distillate can be collected and instruments begin to float. If the distillate is collected and its density is measured with the buoyancy of a spindle, the alcohol content can be determined using a table. While the foreshots are running, the alcohol content of the distillate drops from around 85 to 75 % vol.

However, this is not the only instrument that needs to be observed. The density of the liquid depends very much on its temperature. For this reason, the temperature of the liquid is also measured and the density corrected accordingly. The alcohol content of the distillate can then be read off the density and temperature from a table hanging next to the spirit safe.

Foreshot

It is not poured away but channelled back into the low wines receiver. However, the foreshots are not enriched by this constant backflow. This is where the true magic of distillation comes into play. Catalytic reactions with the copper in the spirit still convert the aggressive foreshots into pleasantly aromatic substances. This is a constantly repeating process and so the amount of foreshots in the spirit still remains constant.

After the foreshots have arrived back in the low wines receiver, the stillman switches the distillate flow in the spirit safe and directs the centrepiece into the spirit receiver for subsequent cask filling. The spirit receiver is basically just the tank in which the raw spirit is stored until it is filled into the barrels, i.e. the alcohol collection tank. The blessing of a customs official is required for filling the barrels, which is why this intermediate storage facility exists. The spirit receivers have different shapes and materials, sometimes round, sometimes square, sometimes metal, sometimes wood. If the stillman switches the distillate flow too early, the whisky tastes too aggressive. If he does it too late, it does no harm, because the liquid that is channelled into the low wines receiver is produced again during the next spirit distillation. No alcohol is wasted in this way.

Middle Cut

Distillation of the centrepiece must be carried out slowly and carefully. If the still is heated too high, the reflux of condensing, higher-boiling substances on the still wall to the lyne arm may not function properly and higher-boiling substances such as fusel oils may also pass over into the collecting vessel. Fusel oil is a mixture that can contain medium and higher alcohols, fatty acid esters and other substances such as terpenes, aldehydes and carboxylic acids. It is produced during alcoholic fermentation as a by-product of yeast metabolism from amino acids and serves as a flavour and aroma carrier in alcoholic beverages. However, fusel oil is also suspected of being partly responsible for 'hangovers' in the form of headaches caused by alcohol consumption. During the collection of the centrepiece, the so-called middle cut, over a distillation period of around three hours, the alcohol content drops from 75 to 60 % vol.

Faints

Nevertheless, distillation continues at 60 % vol. after the switchover. The fusel oils (faints) that now appear are fed back into the low wines receiver for copper catalytic conversion during the next distillation. The distillation of the faints continues for a long time and is only stopped when there is a residual alcohol content of 1 % vol. in the still in order to avoid losing valuable alcohol with the liquid remaining in the spirit still (spent lees).

It is rare to have the opportunity to see the inside of the Low Wines Receiver. It contains a milky grey-white mixture of alcohol and water on which the thin oily layer of fusel oils (faints) floats.

Distillation balance 2

This completes a full distillation. The distillation balance for the second distillation in the following table shows the amount of raw whisky produced. In the assumed example of 30,000 litres of wash with 10% alcohol by volume, the alcohol quantity of around 2,780 litres obtained by distillation corresponds to a yield of 9.27%.

| Low Wines | Raw whisky | Spent Lees | Faints & Foreshots | |

|---|---|---|---|---|

| Total in litres | 11.252 | 4.117 | 3.376 | 3.759 |

| Alcohol content in % vol | 25% | 67,5 % | 1% | |

| Alcohol in litres | 2.813 | 2.779 | 34 |

Particular attention should be paid to the faints & foreshots returned for re-distillation. They increase both the amount of liquid in the low wines and their alcohol content. As they are a continuous item from one distillation to the next, they are not recognised in the balance sheet. This initially confusing situation also causes the alcohol content of low wines to fluctuate in the literature and when mentioned in the distillery in a range of 20 to 27 % vol. For our exemplary balance sheet, we have simply assumed an average of 25 % vol. in the first distillate and 67.5 % vol. in the second. The fact that the volume of spent lees is 30% of the first distillate is also an example and, like all the values given in the balance sheets, must be regarded more as a guide than as a characteristic value.

New Make Spirit - White Dog - White Whisky

The freshly distilled alcohol that comes directly from the still, whether pot still or column still, is called new make spirit, raw spirit or white dog before it is filled into the barrels for maturation. It often has an alcohol content of over 60% vol. It is raw, unripe and very intense. It is important to note here that it is not whisky, as it has not yet been aged. Craft distilleries often offer this new make spirit for sale. On the one hand, to give customers this flavour, but certainly also to generate revenue before the spirit can be sold as whisky. The flavour profile can vary greatly depending on the grain used, from sweet to fruity and spicy.

The Master Distiller

The English term 'Master Distiller' could be roughly translated as 'master distiller' or 'master distiller'. In practice, the title of Master Distiller is not clearly defined. In most cases, it refers to the distilling expert, but sometimes the master distiller also means the manager of the entire distillery.