Maker's Mark

Makers Mark is on the rise and needs to increase its production capacity. But they don't want to change anything to the production process. So they just multiply their existing production equipment. They already did this around the turn of the millennium with the second still and more fermenters. In 2015 they install a third similar still and even more fermenters of the same kind.

Details about the Distillery

The Whisky

The Makers Mark distillery only has a few bottlings and the distillery character is very clearly defined. The palette of the Maker's Mark is very forward with light flavours and the absence of any bitterness.

Production

Makers Mark is on the rise and needs to increase its production capacity. But they don't want to change anything to the production process. So they just multiply their existing production equipment. They already did this around the turn of the millennium with the second still and more fermenters. In 2015 they install a third similar still and even more fermenters of the same kind.

Mashing

The mash bill of Maker's Mark is made of 70% corn, 16% soft winter wheat and 14% malted barley. There are two specialities about this mash bill. First of all with the use of malted barley you don't have to add enzymes to the process of mashing. The natural enzymes of the malt split the starch of the gains inside the mash tun.

The other speciality is the use of wheat instead of the more common use of rye. The wheat gives the whiskey a much softer taste, but also doesn't add to the spiciness of the whiskey.

Before the mash is assembled in the tun the grains have to be milled. The distillery uses a roller mill that crushes the grain between two big rolling cylinders. The roller mill has the advantage that it can be set to a very precise width and therefore defines the coarseness of the grist exactly. A coarse grist is chosen because this keeps the proteins of the corn mostly in one compact broken piece. The starch of the corn however is broken very easily and released into the mash tun. Maker's Mark cooks the mash very carefully to not release to much of the proteins that make the whiskey bitter and unpleasant. The resulting process is a cooking at a maximum of 100°C (212°F) with normal atmospheric pressure. This may take longer than pressure cooking, but keeps the flavour profile as wanted.

Fermentation

Maker's Mark has its own yeast strain and takes great care in preserving this yeast. It produces very fruity and light aromas. One way of ensuring that the yeast grows in a clean and orderly way is to add hops to the growing yeast. Hops is the perfect ingredient for growing yeast and suppressing any unwanted bacteria. But the yeast is only added to the yeast tank and ensures the growth of the yeast in an early stadium. The yeast is only there to prevent vinegar bacteria and other harmful stuff from growing. It does not add to the flavour of the whiskey.

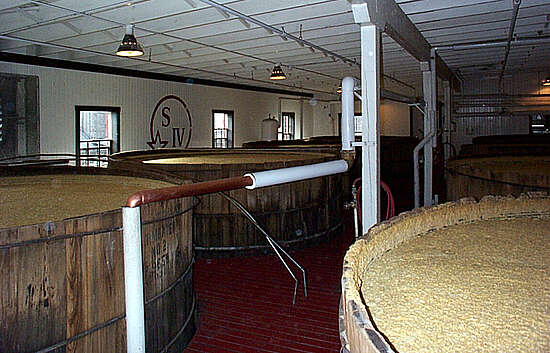

The fermentation is carried out in relatively small wooden fermenters. To ensure the right flavours the speed of the fermentation is keep relatively low.

Stills

The column stills of Maker's Mark are one of the shortest in the industry. This works well with the concept of the production of their beer. They prepared the beer in a way, which is favourable in terms of the brewed aromas. During distillation they do not want to eliminate these flavours from their product. The still has only 17 layers in a 4.5 story tall building. In addition they only distil to 60 % ABV (120 proof). The result is a relatively low ABV white dog that is missing any bitter components.

Maturation

The alcohol strength at which the white dog is barrelled is very low (55% ABV). First you would expect to loose less product due to evaporation (Angel's Share) and therefore it would be cheaper. But the other economic factor is much more important. The Maker's Mark distillery needs to fill a lot more barrels to produce the same amount of whiskey. This is a major factor to the price as the cost of the barrels is one of the major cost influences.

On the other hand the whiskey can interact more with the cask and you need less dilution after the maturation. This is another great benefit of barrelling low.

But quality doesn't end here. The distillers and warehouse managers of Maker's Mark took a detailed look at the flavours inside the wood and found out that seasoned wood had a very different flavour profile than fresh cut wood. Therefore Maker's Mark set as one of their rules, that the staves have to be seasoned for at least nine month in the open. This reduces the amount of tannins in the wood and lets the whiskey mature in a milder way.

Everything is preset for a good maturation: Low AVB and a good seasoned fresh American oak cask. How does the Maker Mark maturation work? The warehouses are four to seven stories tall and have a great difference in heat from bottom to top. The newly filled barrels are stored at top. Here you have the fastest additive maturation. The barrel breathes a lot due to the heat cycles from summer to winter. A lot of the vanilla and caramel flavours come from this phase. Later the whiskey is moved to lower levels in the warehouse. Here the whiskey matures in a subtractive way and removes the last unwanted flavours. During this time the warehouse managers taste the barrels and chose the ones that are ready to be filled.

Visitor Centre

The Maker's Mark distillery is open to the public and is expanding its visitor business with every year. You can visit any steps of the production on the tours. At the end of the tour you will also do a guided tasting through the products of the distillery. One special feature is the waxing of the bottles. After putting on the safety equipment you can wax your own bottle with the Maker's Mark trademark red wax. (For more infos watch the video above.)