The cask ageing of Whisky

A crucial step in the production of whisky is the maturation of the whisky in oak casks. During this process, the whisky absorbs aromas that shape its flavour and colour. Various factors influence the maturation process. These include the origin of the cask, the duration of storage and the environment. Whiskies from one and the same distillery can nevertheless have different flavour profiles, as even the smallest changes in the maturation process have a major impact. To track down these subtle differences, experts analyse chemical components such as esters, tannins and lactones in parts per million (ppm) and parts per billion (ppb). A tiny proportion can influence the flavour for decades. The wooden barrel is a key factor that has a decisive influence on the ageing process!

Influences on the flavour of Whisky

The cask maturation of the whisky has one of the greatest influences on its later flavour. It complements and changes the distillery character that the whisky has acquired during distillation. Single malt whisky in particular is stored in casks for a long time and therefore has a lot of time to absorb flavours from the wood. However, it is not just the length of the maturation process that makes it so influential. Above all, it depends on the type of cask. It plays a key role in determining how the flavour of Scotch whisky, bourbon and Irish whiskey changes over the years.

Cask types - Finishing - the post-maturing of Whisky

What was in the barrel before?

Ex-sherry - what does that mean? This is about the previous contents of the cask; what was the cask previously filled with?

The liquid that was previously stored in the cask has a major influence on the flavour of the whisky. Ex-sherry and ex-port wine casks were traditionally used at the historical beginning of whisky maturation. They were available in sufficient quantities due to the transport of these strong wines to Great Britain. With the rise in popularity of Scotch whisky, ex-bourbon casks were increasingly used and became the quasi-standard after the Second World War.

In addition to the traditional sherry and port wine casks, maturation or post-maturation in barrique casks of all kinds has now also become common. Rum casks and beer barrels have also arrived in whisky finishing.

| Original content | Category | Influence on the flavour |

|---|---|---|

| Bourbon | whiskey | Vanilla, sweetness, caramel |

| Amontillado | Sherry | Sweetness, nutty, dry, fresh, acidity |

| Fino | sherry | Light fruit, sweetness, dryness, light wood |

| Manzanilla | sherry | Salty, dryness, sea flavours, fresh, some fruit |

| Moscatel | sherry | very sweet, dark fruit, sultanas, syrup |

| Oloroso | sherry | deep, dark, nutty, dark ripe fruit |

| Palo Cortado | Sherry | Rich, sweet, dry, sweet spices, fruit |

| Pedro Ximénez (PX) | sherry | very sweet, dark fruit, sultanas, syrup |

| Port (sweet) | Port wine | sweet, dried fruit, spicy flavour |

| Port (semi-dry) | Port wine | slightly sweet, dried fruit, spicy flavour |

| Port (dry) | Port wine | dry, dried fruit, spicy flavour |

| Ruby Port | Port wine | very fruity, dark fruits, sweetness, dryness |

| Tawny Port | Port wine | Very fruity, nutty, caramel, chocolate and tobacco flavours |

| Madeira | Liqueur wine | Spicy, slightly fruity, sweet, dry |

| Marsala | Liqueur wine | sweet, complex, spices |

| Amarone | Red wine | Tannins (bitter), dry, sultanas, ripe fruit |

| Barolo | Red wine | Fruit, tannins (bitter), dried fruit, heavy flavours |

| Bordeaux | Red wine | Strong red fruit, grapes, berries |

| Chardonnay | White wine | light, fresh, acidic, tropical fruit |

| Muscatel | White wine | floral, sweet, citrus, peach |

| Sauternes | White wine | Sweet, lemon zest, acidity, light fruit |

| Tokay | White wine | Light fresh fruit (lemon, mango), very sweet |

| Burgundy | Burgundy wine | very fruity, slightly sweet, slightly dry |

| Rum (white) | Spirit | sweet, molasses, vanilla, tropical fruit, almond |

| Rum (dark) | Spirit | sweet, syrup, dark fruit, oak caramel, vanilla |

| beer | beer | Hops, malt |

| Virgin Oak | - | Vanilla, cloves, caramel or tannins |

| Mizunara Oak | - | fruity, sweet |

This video is about finishing, the post-maturing of single malt whisky in different casks, as well as the question of why whisky is actually post-matured and whether a longer post-maturing period is really better.

Which wood is used for the cask?

Only oak may be used for the storage of Scotch whisky and Kentucky Straight Bourbon. There are two main types of oak used for the production of casks.

| Type of oak | Flavour influence |

|---|---|

| American white oak (Quercus alba) | Vanilla and caramel, soft and mild |

| European oak (Quercus robur and petraea) | Spicy and bitter notes |

| Mizunara oak (Quercus crispula) | Sandalwood, coconut and oriental spices |

| Maple (Acer) | sweet, maple syrup |

The American white oak is mainly found in the east of the USA and in parts of Canada and is used for the production of barrels for bourbon and Tenneessee whiskey. Its growth is relatively vigorous for oaks. The wood has a high density of 770 kg/m3and contains a lot of monogalloyl glucose, which is responsible for the typical vanilla notes in bourbon.

European oak, on the other hand, grows more slowly and has a lower density (720 kg/m3) than its American relative. The gallic acid it contains is a vegetable tannin and belongs to the gallotanins. It causes the bitter notes in the whisky. European oak gives off significantly stronger and spicier flavours than American white oak. It is mainly used for the production of barrels for European wines and strong wines such as sherry.

Mizunara oak is very widespread in the forests of North East Asia, where it is mainly used for high-quality furniture. Due to its high density and thin fibres, the staves have to be cut along the fibres, which never grow completely straight. The oak also lacks waterproofing oil enzymes, which means that considerably more whisky evaporates during the maturing process than when maturing in American or European oak. Despite these characteristics, which make it much more difficult to use for whisky casks, Mizunara oak became increasingly popular for maturing whisky at the beginning of the 20th century. Not least because of the special flavours it gives off to the whisky, which are reminiscent of sandalwood, coconut and oriental spices, for example.

Maple grows in many parts of the world, including Eurasia, North Africa, Central and North America. With its relatively low density of 653 kg/m3, it is mainly used in the production of Tennessee whiskey: this is filtered through a charcoal layer of sugar maple before being stored in barrels, which makes it particularly smooth. In addition, some American whiskey producers mature their spirits in maple barrels to give the whiskeys the sweet notes of maple and maple syrup.

While only oak may be used in the main whisky-producing countries of Scotland and the USA, other types of wood such as chestnut are used in other countries.

What happens in the cask?

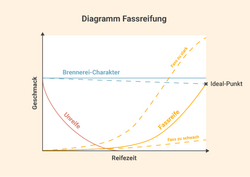

During barrel maturation, three fundamentally different effects play a role in the barrel. Let's take a look at the following diagram. The flavour is plotted vertically. On the horizontal axis we find the corresponding time.

1. subtractive maturation

An unripened, fresh whisky has a sharp, metallic aftertaste. Anyone who has ever had the opportunity to take a fresh sample from a still or spirit safe will remember this unpleasant flavour forever.

As the spirit matures in the cask, this unwanted flavour is reduced more and more along the red line. After 5 to 8 years, it usually disappears. As this is a reduction in flavour, experts refer to it as subtractive maturation. This is also the reason why there are almost no malt whiskies with an age of less than 8 years.

2. additive maturation

As the whisky matures, it absorbs flavours from the cask. Initially these are the flavours of wood in general, but also vanilla, caramel and oak in particular. The wood passes on its character to the whisky. This additive maturation is reflected by the yellow lines. An old, less active cask will influence the whisky along the lower dotted line, a 1st fill cask made from European oak corresponds to the upper dotted yellow line.

3. interactive maturation

But it is not only maturation and cask character that determine the flavour of the whisky. Above all, the special distillation and the malt used determine the basic character of a malt whisky. The upper, horizontal, blue line describes the distillery character, which remains roughly constant over time. In fact, the peat smoke more or less diminishes over the years, which leads to a weakening of the distillery character.

And so it is clear - the barrel determines the result!

The green lines show the various cask influences during interactive maturation. As the alcohol in the whisky extracts flavours from the cask, we are basically dealing with dissolution processes. Initially, the curves rise sharply and then flatten out more or less significantly. Only the middle curve is more or less ideal. The interactive maturation ideally combines barrel and distillery character. The upper dashed curve rises far too quickly and the barrel character begins to dominate. The lower dashed line shows a cask that has already lost most of its flavour. Even after many years, the distillery character dominates.

The upper curve is typical of fresh barrels made from European oak. The cask character very quickly dominates and the whisky is overwhelmed by the wood. The lower curve stands for barrels that have been used too often and are already leached out. Whilst it is possible to reactivate leached casks by reworking them, you are almost helpless in the face of European casks that are too strong. The cask dominates far too quickly and the immaturity may not even have been reduced yet.

But there's a trick that puts everything right again. The keyword is cask finishing. First, the whisky is matured in normal American casks until it has reduced its immaturity and has already absorbed a basic flavour. 8-10 years are sufficient for this. The matured contents are then transferred to European oak casks that have previously contained a wide variety of wines. The 1st fill is important here. After 1 to 2 years, the time has come. The character of the distillery and the barrels have come together in an interactive maturation process to form a harmonious whole.

A pleasant by-product of this maturation are European oak barrels that have lost their extreme character and are now suitable for long-term maturation. However, these refill barrels must not be used for too long so that they are not too depleted.

Fresh European oak is, please excuse the expression, 'almost unbearable'. Only in the Glenlivet French Oak Finish are completely fresh and not previously filled French saloon oak casks used in the finish. Pure European oak maturation is very rare in whisky.

Winemakers have also come to appreciate the extreme flavour of this wood. More and more barrique casks are being used for a short maturation period for southern European red wine. The Scotch whisky industry can also benefit from this.

First Fill - Refill

The age of the cask and its reuse!

Oak casks are very durable and can hold whisky for many decades. However, the flavour that the whisky can absorb from the wood decreases over the years. The cask becomes leached out. Whisky stored in fresh casks therefore absorbs the most flavours.

Bourbon is stored in fresh casks and is already flavoured enough to be bottled after 2-5 years. Scotch whisky matures in used casks that have previously been used for bourbon or sherry, for example. The cask has already released a large proportion of the flavours. Scottish malts therefore only become really good after a longer period of storage. However, this also gives them more time to break down the alcoholic flavour.

Casks are expensive these days. It is therefore common practice in the whisky industry to mature whisky in casks more than once. After 10 years of malt whisky maturation, a cask still contains a lot of flavours and is therefore reused for the next malt. In the industry, they are called refill casks. Refill casks are reused for up to around 30 years.

However, it is clear that the influence of the cask on the flavour is becoming weaker and weaker. It is not surprising if a whisky from a refill cask has absorbed very little flavour - and therefore colour. On the labels of some bottlers you will sometimes find information such as Refill or First Fill, which stands for the degree of utilisation of the casks. This gives you, the customer, an indication of the approximate intensity of the cask flavour. However, it is also common to colour whisky with flavourless caramel. In this case, the cask flavour is disguised.

Nowadays, it is becoming increasingly common to recondition casks, as this is cheaper than buying new casks. This does bring out the oak flavour again. New sherry, port or wine flavours cannot be produced in this way. These 'rejouvenated' casks make whisky very flavourful in a short time.

Cask sizes

Size also plays a significant role in the maturation process. A whisky matures faster in a smaller wooden cask, as there is relatively more surface area available per litre of whisky enclosed. The exchange of substances between the wood and whisky is therefore faster in smaller casks.

There are many cask sizes. However, there is no uniform ISO standard for certain types. Sometimes the cask sizes that have developed historically are also a unit of measurement. The hogshead, for example, is an old English measure of volume.

The most important barrel in whisky production is the American Standard Barrel (ASB). It holds around 200 litres. ASBs are also the 'raw material' for the production of Scottish hogsheads. These are barrels with a capacity of around 250 litres. If an ASB is broken down into individual staves and slightly larger rings (hoops) are used to assemble it, the same staves can be used to assemble barrels with a larger diameter. From four to five ASBs you get about 3 hogsheads. Even larger barrels cannot be assembled from the staves. The trapezoidal shape of the staves, originally intended for 200 litres, prevents a larger diameter. Sooner or later, the barrels would leak at the gaps.

European oak is processed in Spain and Portugal into barrels of 500 to 600 litres. These barrels are ideal for maturing sherry and port wine. The Scots call these barrels 'butt or sherry butts' and 'port pipes'. Nowadays, more and more butts are being made from American oak for cost reasons.

| Cask size | Capacity in litres |

|---|---|

| Standard sizes for whisky: | |

| Quarter Cask | 50/125 |

| Bourbon Barrel (American Standard Barrel) | 208 |

| Hogshead | 250 |

| Butt | 500 |

| Port Pipe | 500-650 |

| Octave | 50 |

| Other sizes: | |

| Blood Tub | 30-50 |

| Bordeaux | 225 |

| Barrique | 225 |

| Sherry Hogshead | 245 |

| Cognac | 300 |

| Puncheon | 500 |

| Madeira Drum | 650 |

Small Batch

The name Small Batch means 'small cask'. However, it is not a small cask in which the whisky is stored. Rather, only a relatively small number of selected casks from a distillery are married together and bottled. This primarily occurs in the USA.

There are no fixed rules as to how many casks are blended. Small batch whiskies are produced in limited editions. The exciting thing about each individual small batch bottling is the result that the master blender has created.

Single Cask

The single cask bottling is something very special! Normally, casks from a distillery are married by the master blender to ensure the consistent quality of a single malt. With a single cask or single barrel, individual casks are selected from the warehouse that are worth bottling in their pure form.

Each individual cask is very unique and has its own character and colour. Depending on the size of the cask, this results in only a limited number of bottles - around 100 to 300 bottles per cask. The whisky is often bottled at cask strength and without chill-filtering.

A single cask whisky is therefore rare and more expensive than a standard whisky. Due to their limited availability, single cask bottlings are particularly sought after by collectors and are often released as limited editions.

STR Cask

shaved - toasted - recharred

The so-called 'STR Cask' is a special type of cask. STR stands for 'shaved, toasted and re-charred', i.e. 'shaved, toasted and re-charred'. The casks are produced using a special process developed by the well-known, now deceased whisky expert Dr Jim Swan. The production process for STR Casks is as follows: fresh red wine hogsheads are taken and their bottoms are first removed. The outer layer of wine-saturated oak is thenshaved away to expose the combination of the lightly saturated oak and the fresh virgin oak. The shaving has removed some of the stronger flavours from the surface of the oak, creating a more subtle red wine influence. The exposed inner layer is thentoasted again to caramelise the sugars and vanillins from the fresh white oak. Oak chips from staves already used for maturing whisky are used to heat the cask during toasting. This brings out the spicy and sweet notes from the casks particularly well. Finally, the casks arere-charred to extract as many flavours and aromas as possible from the cask. Toasting and re-charring also ensures that undesirable chemical compounds such as lignin, cellulose or hemicellulose are broken down and the bitter tannins are removed.

The STR process therefore produces a combination of virgin oak (fresh white oak) and first fill red wine barrels. Whisky matures faster in fresh white oak barrels than in barrels that were previously filled with bourbon, sherry or others. This elaborate process ensures that the spirit matures quickly and intensively, as well as giving the whisky subtle fruity red wine flavours.

Evaporation during cask ageing - Angels' Share

The beautiful expression 'Angels' Share' means 'share for the angels' and in the whisky industry generally refers to the proportion of whisky that evaporates during the maturation period in the cask. The alcohol-water mixture of the whisky expands in the warm summer months and contracts again in the cold winter months, allowing the surrounding air to "breathe" through the pores of the oak wood. Whisky normally loses between 0.5 % and 1 % of its alcohol content per year during maturation. However, in addition to the alcohol, some of the water in the whisky also evaporates. The loss of liquid is therefore significantly higher than the loss of alcohol. It amounts to up to 2 % per year. As alcohol has a higher vapour pressure than water at the same temperature, more alcohol than water (almost) always evaporates and the alcohol content in the cask drops.

Various factors such as ambient temperature, humidity and the type and size of the barrel influence the amount of Angels' Share. In regions with a cool, constant temperature, the angels' share is lower than in hot climates.

However, there are rare exceptions! Maturation in a dry and hot environment leads to increased evaporation of the whisky's water content. Near the roof of new, tall warehouses, it can get so hot that the alcohol content of the whisky rises to 66%-67% during maturation. The increase in alcohol content leads to different reactions with the wood and the development of different flavours. Most Scottish distilleries fill their whisky into casks with an alcohol content of 63.5%, as this is a reasonable compromise between a short maturation period and alcohol evaporation.

Evaporation plays an important role in the maturation of whisky. The alcohol content changes and the oxygen content in the cask increases due to the space released, which triggers oxidative maturation. These processes cause the colour, aroma and taste of the whisky to develop.

For a detailed explanation, watch the following video. Horst Lüning explains the physical processes involved in the evaporation of whisky during cask maturation. He uses a bottle to calculate the loss of alcohol.

The cask warehouse

Where is the cask with the fresh distillate stored for the next few years?

There are different types of warehouses. The construction and the way in which the casks are stacked in the warehouse influence the finished whisky.

Dunnage Warehouse

A'Dunnage Warehouse' is an old, traditional warehouse without windows, usually one or sometimes two storeys high. A maximum of three barrels stacked on top of each other are stored on these floors. The air circulation in the Dunnage Warehouses is said to be particularly conducive to good whisky maturation. Even in summer, it is cool and humid here. The construction of most Dunnage Warehouses is very simple and traditional: clay floors, thick stone walls and a slate roof are sufficient to provide a home for whisky casks. The name of these warehouses is also derived from the type of construction. Dunnage' means 'dunnage', indicating the simple nature of these warehouses.

This type of warehouse is not efficient for distilleries as there is only room for a few barrels. In addition, the barrels usually have to be moved by hand. Dunnage warehouses are therefore less common in distilleries than the so-called'racked warehouses'.

Racked Warehouse

Modern 'racked warehouses' have been around since the 1950s. Here, too, the name says it all: 'racked' is the English word for 'stacked', because a 'rack' is a shelf. They are built from bricks, concrete and steel and have solid floors. These warehouses have space for huge racks on which 15 to 20 barrels can be stacked on top of each other. Racked warehouses are built correspondingly higher, with thinner walls and tin roofs. Due to the design, the internal climate is much more dependent on the outside temperatures and there are large temperature differences between the lower and upper rows of barrels. The barrels are often stored upright rather than horizontally, so that the warehouse workers can move them more easily. This is done on a large scale with forklift trucks.

Palletised Warehouse

In the so-called 'Palletised Warehouse', the name says it all: here, pallets loaded with upright barrels are stacked on top of each other. Depending on the type of barrel, four or six barrels are placed on one such pallet. The drums are held together with a metal frame and can be moved with a forklift truck or crane. Palletised warehouses have the advantage that they are very space-saving and offer a high storage capacity. The pressure of the upper pallet on the drums below can be problematic, which can lead to so-called 'leaks', i.e. cracks in the drums.

Dunnage Warehouse vs. Racked Warehouse

The biggest difference between the two main types of warehouse lies in temperature regulation. Dunnage warehouses offer a more stable temperature and humidity, while racked warehouses have a more varied climate due to their thin walls and tin roofs. This affects whisky maturation as temperature fluctuations cause the whisky to expand in the cask and draw more flavours from the wood. In an environment with higher humidity, whisky generally matures more slowly.

There is no clear preference for either type of cask, as the choice of cask is made by the Master Distillers and Master Blenders who aim to produce the best whisky possible!